Overcoming Integration Challenges in Manufacturing: The Power of a Unified Namespace

In today’s fast-paced manufacturing environment, companies are increasingly relying on software solutions to drive operational efficiency and digital transformation. However, the challenge lies in the fragmented nature of off-the-shelf software solutions. These software tools, often purchased from different vendors, can create significant integration challenges that hinder productivity and increase costs. At Green Groove Technologies, we believe the key to overcoming these challenges is by embracing a Unified Namespace (UNS), which can simplify integration, streamline data management, and unlock greater value from your software investments.

The Challenge of Buying Off-the-Shelf Software

When purchasing software solutions from multiple vendors, manufacturers often face several challenges, including:

- Integration Complexity: Different software packages may use different data models, protocols, and formats, making it difficult to integrate them into a cohesive system. This leads to manual workarounds, custom development, and costly integration projects.

- Data Silos: Each system operates in its own silo, creating gaps in data flow and accessibility across the enterprise. This results in missed opportunities for real-time insights and decision-making.

- Slow Implementation: Even with a clear vision, implementing these disparate systems into a unified whole takes time. The lack of interoperability slows down your digital transformation journey and impacts overall productivity.

- High Costs: The costs associated with integrating, maintaining, and upgrading multiple software solutions can quickly add up. These additional expenses can eat into the ROI of your software investments.

While building a UNS helps solve some of these integration challenges, it often requires significant time, effort, and resources to implement.

Why a Unified Namespace is the Solution

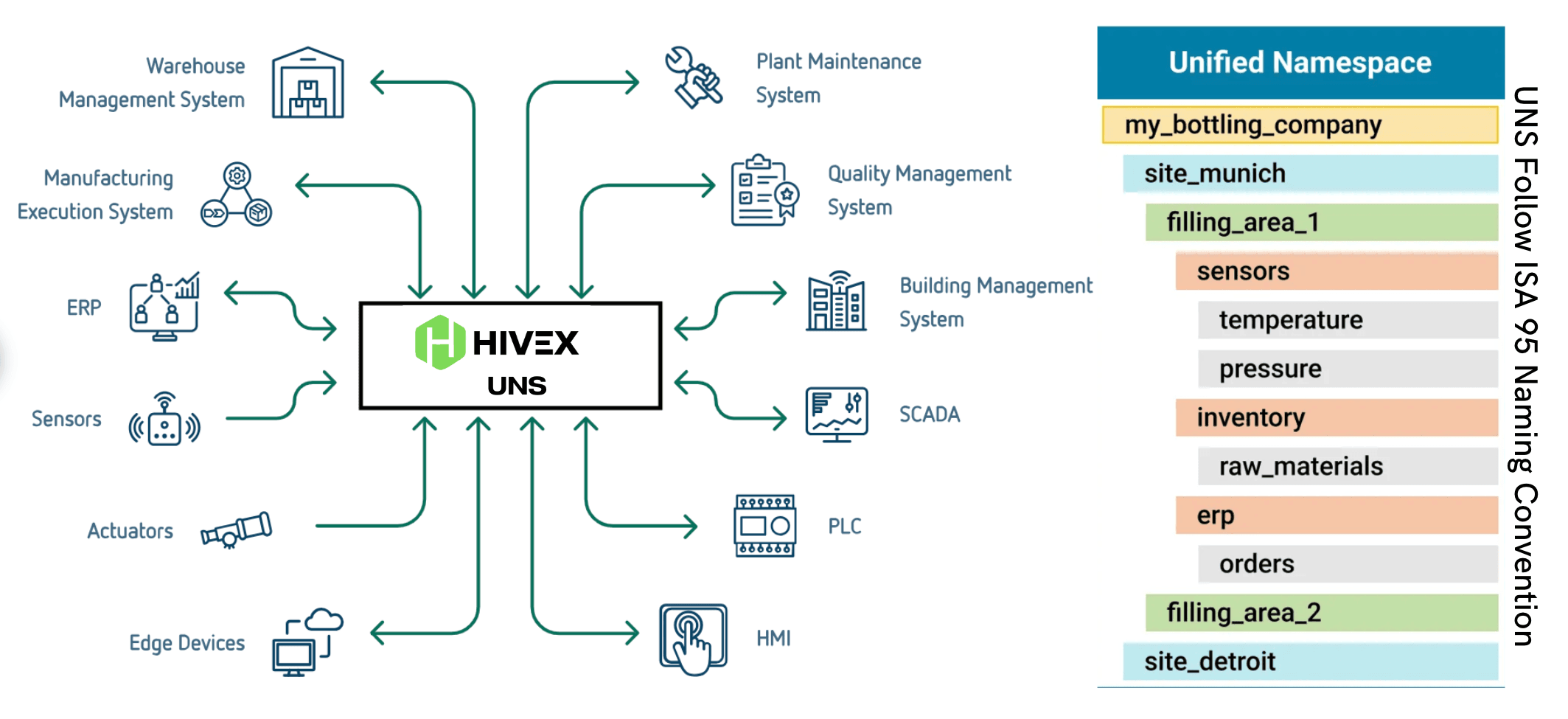

A Unified Namespace (UNS) is a centralized architecture that harmonizes data across disparate software systems, providing a single source of truth for enterprise-wide information. By consolidating data in a standardized, accessible format, UNS helps manufacturers overcome the limitations of off-the-shelf software solutions and enables seamless communication between different systems. Here’s why UNS is the ideal solution for manufacturers:

- Simplified Integration: UNS reduces the complexity of managing multiple systems by serving as a central data hub. By using common data standards and protocols (like ISA-95), UNS makes it easier to integrate different software applications, resulting in fewer integration points and faster implementation.

- Real-Time Data Access: With UNS, data flows freely between systems, enabling real-time access to critical information. This immediate visibility allows manufacturers to make proactive, data-driven decisions, optimize production schedules, and reduce downtime.

- Cost Reduction: Implementing UNS reduces the need for custom integrations and ongoing maintenance of separate systems. With fewer integration touchpoints, manufacturers can save on development costs and reduce technical debt. UNS also reduces operational costs by automating data exchange and improving the efficiency of existing systems.

- Scalability and Flexibility: As your manufacturing processes evolve, UNS allows you to easily scale and add new systems or applications without disrupting existing operations. This flexibility ensures that your IT architecture grows with your business, future-proofing your digital transformation strategy.

Getting Started with UNS: A Step-by-Step Guide

Implementing a UNS in your manufacturing environment doesn’t need to be a daunting task. At Green Groove Technologies, we’ve outlined a straightforward roadmap to help you get started:

- Assess Your Current Environment: Before diving into a UNS implementation, start by evaluating your existing software landscape. Identify the systems you currently use, their integration challenges, and the data silos that exist. Understanding these pain points will help you design a UNS that effectively addresses your needs.

- Design Your Data Architecture: A crucial step in implementing UNS is designing your data model. Use standards such as ISA-95 to create a clear enterprise hierarchy. This ensures that all your data flows through a consistent structure, making it easier to integrate different systems.

- Choose the Right Protocols: To enable seamless communication between different software solutions, implement IIoT protocols such as MQTT. These protocols allow data to be transmitted in real-time and ensure that all systems within the UNS can communicate effectively.

- Start Small with Pilot Projects: Rather than overhauling your entire system in one go, start with a pilot project. Choose a specific area of your manufacturing process to deploy UNS and evaluate its effectiveness. This phased approach reduces risk and allows you to adjust the architecture as needed.

- Scale Across Your Organization: Once the pilot is successful, gradually scale your UNS deployment across the enterprise. By expanding slowly, you can ensure that each system is properly integrated and that the benefits of real-time data are fully realized.

Calculating the ROI of UNS

Implementing a UNS isn’t just a technical decision—it’s a strategic one that can deliver significant ROI over time. Here’s how to calculate the benefits:

- Reduced Integration Costs: The cost of integrating multiple off-the-shelf software solutions can quickly add up. With UNS, integration complexity is reduced, leading to lower costs for system integration, maintenance, and upgrades.

- Improved Operational Efficiency: UNS enables faster access to real-time data, which translates into more efficient production, fewer downtime instances, and quicker troubleshooting. This results in better resource utilization and lower operational costs.

- Enhanced Decision Making: With all systems connected through a centralized data hub, decision-makers can access up-to-date, reliable data. This leads to more informed decisions, improved production planning, and optimized supply chain management.

- Future-Proofing: By adopting a scalable architecture, UNS ensures that your digital transformation strategy remains flexible and adaptable. As new technologies and systems emerge, they can be integrated with minimal disruption to your existing operations, providing long-term value.

Conclusion

At Green Groove Technologies, we understand the challenges manufacturers face when dealing with disparate software systems. A Unified Namespace is the solution to these challenges, offering simplified integration, real-time data access, and significant cost savings. By adopting UNS, manufacturers can unlock greater operational efficiency, future-proof their digital transformation, and gain a competitive edge in an increasingly data-driven world.

Don’t let integration challenges hold you back. Start your UNS journey today, and experience the power of seamless, connected manufacturing systems.