Why Your Manufacturing Operations Need a Smart SaaS Platform

In the age of Industry 4.0, manufacturers are facing an increasing complexity in managing operations. The rise of connected devices, IoT sensors, and advanced manufacturing systems has led to a massive explosion in the volume of data generated. Yet, despite having more data than ever before, many manufacturers struggle to harness it effectively. The result? Siloed systems, poor decision-making, and missed opportunities for optimization.

At Green Groove, we recognize these challenges and have developed a comprehensive Software-as-a-Service (SaaS) platform designed to streamline manufacturing operations by offering a suite of modular applications that integrate both Information Technology (IT) and Operational Technology (OT) in real-time.

What is a Smart SaaS Platform for Manufacturing?

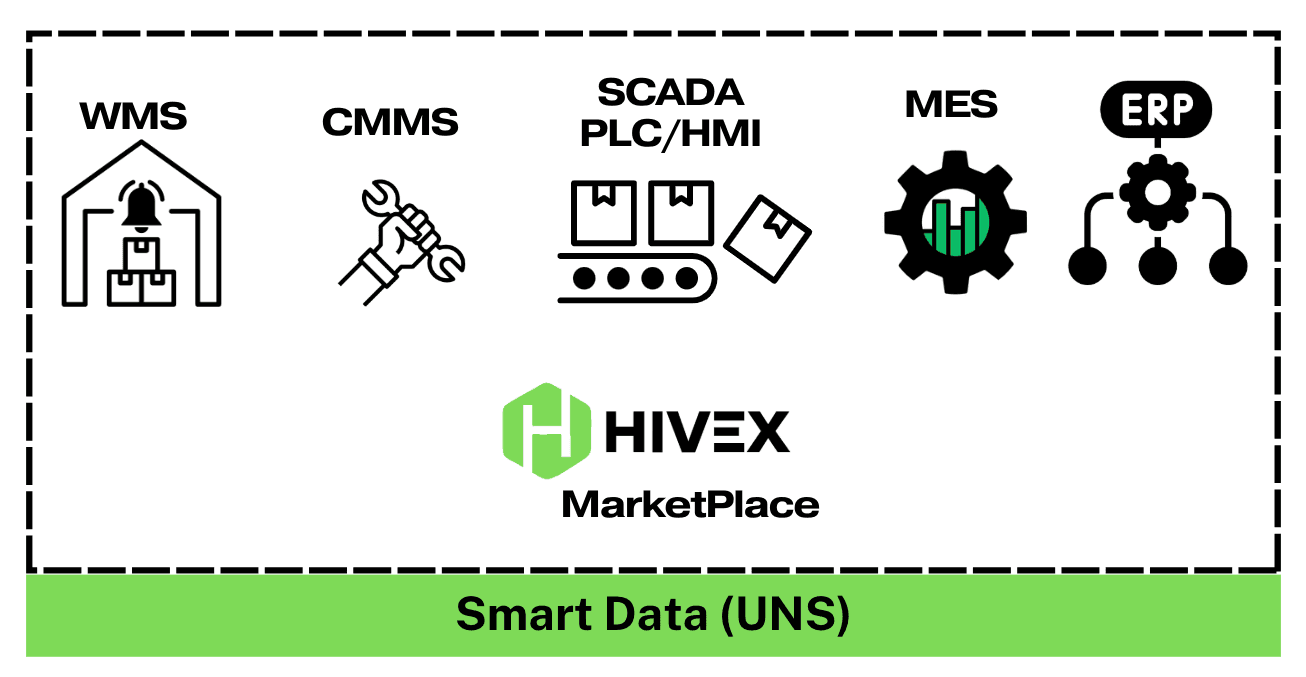

A Smart SaaS platform is an advanced cloud-based system that integrates seamlessly with existing manufacturing infrastructures to provide actionable, real-time insights. Leveraging the power of artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), the Green Groove platform combines data from both IT and OT sources—such as ERP, MES, IoT sensors, and more—into one unified system.

The key to Green Groove’s SaaS solution is its modularity. Manufacturers no longer need to buy expensive, siloed off-the-shelf solutions that don’t speak to each other. Instead, they can access a suite of apps, each focused on specific manufacturing needs, and seamlessly integrate them into their operations. These apps adhere to common standards, ensuring that they work together, providing a comprehensive approach to managing production processes from the factory floor to the back office.

The Benefits of Green Groove’s Modular SaaS Platform

Our platform takes the complexity out of managing multiple disconnected systems by offering a marketplace of modular applications that address both IT and OT needs. Here's how this new approach transforms manufacturing operations:

1. Cost Efficiency with a Modular Approach

Unlike traditional manufacturing software solutions that require large upfront investments, Green Groove's SaaS platform offers a more flexible pricing model. Manufacturers can select and pay for the modules they need, avoiding unnecessary costs for features they don't require. Whether it's predictive maintenance, energy management, or real-time production monitoring, each module is priced according to its functionality, making it cost-effective for businesses of all sizes.

2. Seamless Integration Across IT and OT

One of the biggest challenges faced by manufacturers is the fragmentation between IT (software systems like ERP) and OT (factory floor technologies like MES or PLCs). Our platform solves this by ensuring that IT and OT systems are connected. Through Green Groove's marketplace, manufacturers can integrate all their operations—whether it's inventory management, predictive maintenance, or quality control—into a unified, easy-to-use platform. This connectivity eliminates silos, optimizes workflows, and enhances real-time decision-making.

3. Scalability and Flexibility

Manufacturers are not bound by rigid systems anymore. Green Groove platform allows companies to scale and customize their operations as needed. New apps can be added to the marketplace as your business grows, and you can tailor the system to suit your exact operational requirements. As your needs evolve, the platform evolves with you.

4. Real-Time Data and Insights

Real-time data is the cornerstone of smart manufacturing, and Green Groove SaaS platform ensures that you have visibility into all aspects of your operations. Whether it's machine health, production efficiency, energy usage, or supply chain performance, you can track and act on real-time data from the factory floor to the boardroom. This visibility enables manufacturers to make faster, data-driven decisions that improve productivity, reduce downtime, and drive profitability.

5. Simplified Maintenance and Upgrades

With traditional software, maintaining and upgrading systems can be time-consuming and expensive. Green Groove SaaS platform is always up-to-date, meaning you don't need to worry about constant upgrades or compatibility issues. The platform is continuously improved, with new features and enhancements rolled out automatically, ensuring that manufacturers are always using the latest technology without any added complexity.

6. Faster Time-to-Value

Since Green Groove platform integrates various applications from day one, manufacturers can realize the benefits of smart manufacturing much faster. Instead of waiting months for a complete system to be installed and integrated, the modular approach allows manufacturers to deploy solutions immediately. This not only accelerates the time to value but also allows businesses to begin optimizing their operations from the outset.

Key Modules in the Green Groove Marketplace

At Green Groove, we've created a comprehensive marketplace of modules that cover every aspect of your manufacturing business—from the factory floor to the executive suite. Each module is designed to integrate with others, creating a seamless, interconnected ecosystem. Here’s a look at some of the key modules available in the Green Groove marketplace:

- Predictive Maintenance: Using advanced AI and IoT, the predictive maintenance module helps you track the health of machines and predict failures before they happen. This reduces unplanned downtime, optimizes maintenance schedules, and increases overall equipment effectiveness (OEE).

- Real-Time Production Monitoring: Monitor every aspect of production in real-time, from throughput to quality metrics. This module integrates with MES and IoT devices on the factory floor, providing instant feedback to optimize production processes, reduce cycle times, and increase output.

- Inventory and Supply Chain Management: Manage inventory levels, track supply chain performance, and reduce excess stock. By integrating with ERP and other systems, it ensures that you have a real-time, holistic view of your inventory and procurement processes.

- Energy Management: Track and optimize energy usage throughout your facility. This module integrates with smart meters and IoT sensors to monitor real-time energy consumption and identify inefficiencies, helping manufacturers cut costs and meet sustainability goals.

- Quality Control: Automated quality checks using AI-powered sensors and cameras ensure defects are detected early, minimizing rework costs and improving first-pass yield (FPY). The system integrates seamlessly with the production and supply chain management modules to ensure quality at every stage.

- Workforce and Labor Management: Track labor productivity, schedule shifts, and manage workforce efficiency. By integrating with IoT devices and AI-powered analytics, it provides insights into workforce performance, helping manufacturers improve productivity and optimize staffing levels.

- Advanced Planning and Scheduling (APS): Efficient production planning is key to meeting customer demand. The APS module helps align production schedules with actual demand, reducing lead times and improving on-time delivery rates.

- Sustainability and Compliance: Track emissions, waste, and energy consumption to ensure compliance with environmental regulations. This module provides detailed insights into your sustainability metrics, helping manufacturers reduce their environmental footprint while optimizing resource usage.

Conclusion

The future of manufacturing is data-driven, connected, and intelligent. With Green Groove’s smart SaaS platform, manufacturers can embrace Industry 4.0 without the burden of expensive, disconnected software. Our modular approach gives manufacturers the flexibility to choose the tools they need, integrate them into a unified system, and scale as their business grows.

Ready to take your manufacturing operations to the next level? Join Green Groove today and discover how our smart SaaS platform can transform your business by streamlining IT and OT operations for maximum efficiency and profitability.